Water Well Drilling

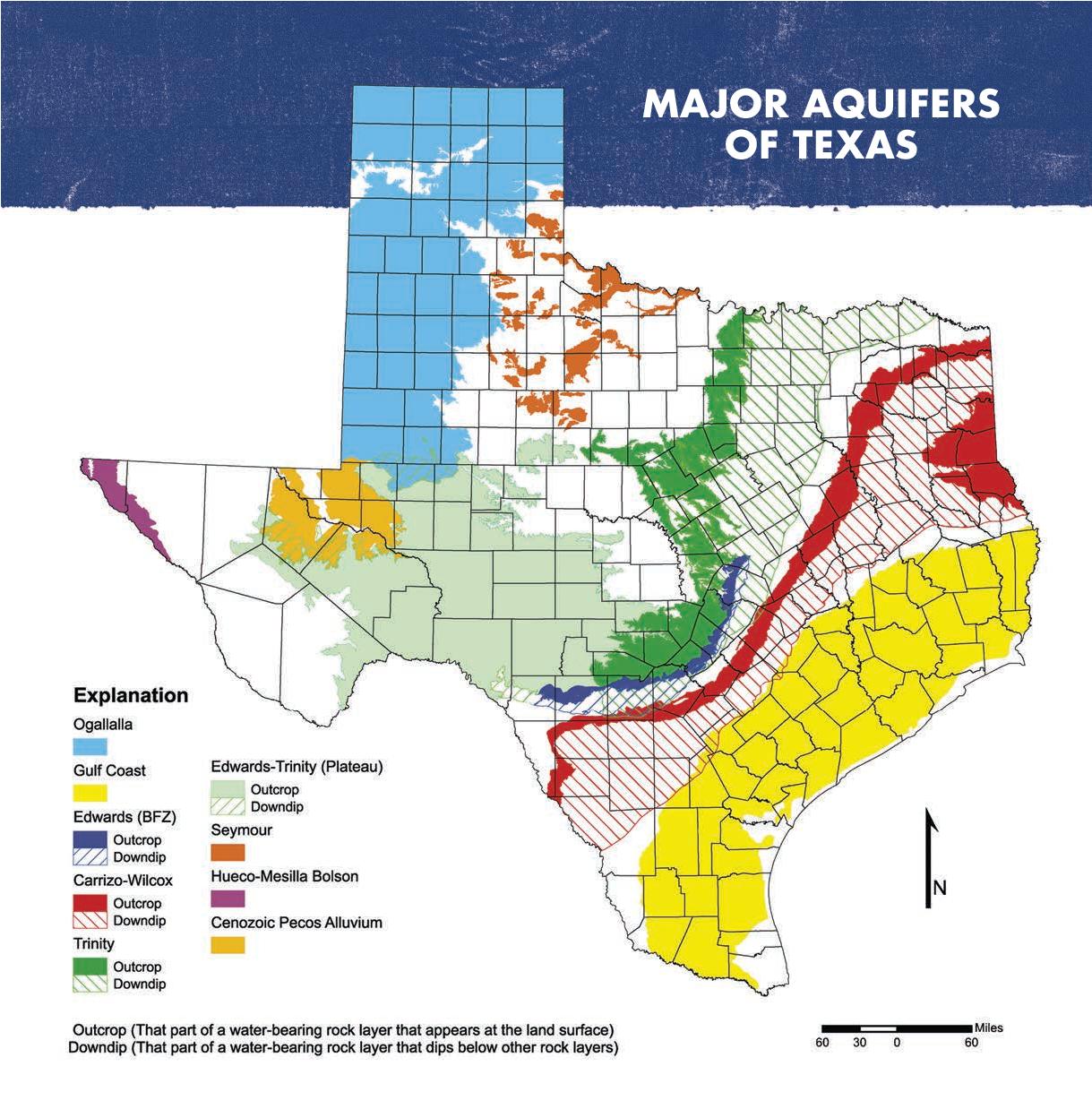

When drilling a new water well in Texas, it needs to be determined how deep the well needs to be drilled and which aquifer to drill to (when there is an aquifer option). But, there are a number of other options that you may not have considered. These include:

- Wellhead Options

- Mud Control

- Site Protection

- Well Location

- Borehole Completion

- Casing

The professionals over at Bee Cave Drilling provided the information for this article.

Wellhead Options

The State of Texas requires that your well casing stick up at least 12 inches above ground. (In certain situations it has to be taller.) But there are two types of Wellhead Options you can choose.

Steel Sleeve - This is the traditional wellhead. The PVC casing sticks up more than 12 inches above the ground. It is surrounded by a larger piece of steel casing that sticks up 12 inches and extends down into the ground 12 inches. The annulus (or void) between the PVC casing and the steel casing is filled with concrete. The water pipe and electric cable must come out of the top of the PVC casing. Typically the pressure tank/storage tank/control box are located nearby. This type of wellhead is recommended if you are going to be building a pump house around the well.

The Pitless Adaptor allows the water pipe to exit the well underground and run to the pressure tank, etc. The electric cable runs in a conduit down the side of the casing and runs underground, along with the water pipe, to the control box or constant pressure controller. The Pitless Adaptor wellhead is preferable when the other well equipment is not located adjacent to the well, and is especially nice for the in-town irrigation wells. The wellhead is small enough to be hidden by some bushes or placed under a fake rock. They can even be painted green or brown to blend in to their environment.

Mud Control Options

Our customers are often surprised by the mess that is created during the drilling process. When drilling on a ranch, this is generally not a problem. We can let the mud created by the drill cuttings and water production flow wherever it wants to go, and it can be left on site. But in residential environments, this is not an option.

On a new construction site, drilling the well before the grading work is completed is the best option. Then the drill cuttings can be moved around or removed as needed during the grading. In these situations, it might be necessary to erect some silt fence to retain the mud onsite, or use drill mud bags made out of silt fence-type material to contain the drill cuttings in one place and to dampen the dust produced during drilling.

Another option is called the No Spill Drill. The company brings a specially modified container to catch all the drilling cuttings and water. Then they haul it off, and you are left with a clean site. This is the most expensive mud control option, but it is a popular choice due to its minimal impact on the landscaping and the quick, easy removal of the drill cuttings.

Site Protection

The drilling rig is extremely heavy – around 60,000 pounds! Most concrete driveways can handle the weight without a problem, but the weight poses a problem for lawns, irrigation lines, sidewalks, and for some cobblestone driveways. It is often needed to bring in one or more support trucks to complete the drilling of the well. These trucks are lighter, but can still cause damage to some lawns, especially if the ground is not perfectly dry.

To limit the impact the weight of the equipment has on your lawn, cover the ground with one or more layers of plywood mats. These mats spread out the weight of the load and lessen the probability that we will damage your property. This type of site protection will most likely be an additional charge.

Well Location

The State of Texas has established minimum distance requirements from property lines, sewer lines, septic systems, and other sources of potential groundwater contamination. The State requires that the well annulus be cemented for at least 10 feet from the ground surface (or 20 feet for a pitless adaptor well). In the city, the State of Texas wants wells to be located at least 5 feet from the property lines and at least 50 feet from any and all sewer lines (both the public sewer main and the line running from the house to the public sewer main).

In areas with septic tanks, the State wants wells to be at least 50 feet from property lines, at least 50 feet from septic tanks, and at least 100 feet from septic fields. (Some groundwater conservation districts may have stricter requirements.)

The State does provide a variance from these requirements. If you have a septic tank but cannot meet these set back requirements, you can pressure cement the first 100 feet of the well by drilling a larger hole and filling that space with concrete. This will allow you to be as close as 5 feet from the property lines, and 50 feet from both the septic tank and field.

If you still cannot select a well location that meets these requirements, you can obtain a variance from the State to lessen these set back distances. However this generally involves drilling a larger hole and pressure cementing the well down to the top of the water bearing formation – which could be several hundred feet.

Other factors to consider in selecting a well location are accessibility and proximity to your power supply. The drilling rig is roughly 40 feet long and 40 feet tall during operation. So it cannot be near power lines or under trees. It also has to be located in order to get a service truck back to the well again in the future to do repairs on the well. So accessibility needs to be considered.

The well pump needs to have power supply from your breaker box. So the closer the well can be to the breaker box, the less you will have to pay for trenching and the electrical run.

Some people factor in visibility to their selection of a well location. However with a pitless adaptor, you can place the well in your front yard and it is virtually unseen.

Borehole Completion

There is another factor that is not an issue for most wells. But if you are located in the western Hill Country of Texas, it may be recommended you consider a different type of borehole completion method than normal.

Gravel Packing is the most difficult, expensive, and time consuming borehole completion method offered, but the extra trouble can be well worth it. For example, if you encounter a stringer of clay or soft limestone in the middle of your production zone, you can produce all of the water available. With the Gravel Packing technique no downward migration of clay or limestone can penetrate through the clay pack that is on top of the gravel pack. This ensures that your water will be clean and you will get the full production of the well. Gravel packing is most commonly used in the Spicewood area.

Open Hole Casing is the least expensive and easiest method of completion. Besides being the quickest to finish of all three options, its other advantage is that you maintain the ability to enter the hole at a later time. However, the disadvantages can be significant. First, your water supply will have limestone silt in it that will need to be filtered out. Moreover, as the well ages, the hole can fill in over several years and cut off the supply of water. This method is typically only used in the granite/dolomite/Ellenberger areas of the western Hill Country.

Neoprene Packer Casing is a compromise between the two other methods: gravel packing and open hole. You can complete the well relatively fast, without the highest expense. The silt and sand are stopped by the rubber packer that is attached to the casing. The main problem is that the packer can leak under high pressure. To prevent this from happening, use multiple packers.

Casing Options

For years, the drillers have struggled with casing collapse. The column on the outside of the casing fills up with seep water, while the water inside the casing pushes back out. When the water level drops during pumping, the water on the outside pushes in on the casing. This is even worse during drought periods. If the pressure on the casing is more than it is designed to handle, then the casing will collapse. This ruins the well and in many cases, captures the pump.

PVC Casing is widely used because of its low cost and efficiency. However, there are different grades of PVC, and some are more likely to collapse than others. As a general rule, use SDR-17 PVC casing for your wells. But for some deeper wells, PVC is not strong enough to protect against collapse.

Steel Casing , for some wells, is necessary. If the collapse pressure is too high, this is the only option. This puts rust in the water and this can cause some problems. The casing can also rust to the point of failure. But each of these issues can be mitigated, depending upon your needs.

Fiberglass Casing – If you are looking for better casing, there is an alternative. PVC casing is limited in size and strength and steel casing rusts. The only product on the market that is as strong as steel and doesn’t rust is fiberglass. They make this stuff so strong, that they run it in oil wells 5 miles deep. The cost is comparable to steel and it will last forever. It can handle temperatures up to 300 degrees. Now, for the first time, the State of Texas is allowing fiberglass casing in wells.

Bee Cave Drilling Answers a Few FAQ's

How do you know when you hit water?

We have a huge air compressor on the rig that blows air down the drill stem. The air comes back up the hole with enough force to move all cuttings up and out of the hole. If the well is producing water, the water will come too. Most of the time, we are actually pumping water into the air stream already, and we are really looking for an increase in the water. If we think we have hit water, we can turn off our water injection pump and check the flow of water with the air compressor alone.

How do you know how much water the well will produce?

There is no definite answer to this question. We are estimating the flow based on what we see flowing from the well. Sometimes, the air pressure in the well can “hold back” on the flow, causing us to underestimate the production capacity. To overcome this, we can release the air pressure for a few minutes, and then reapply it after the well has built up a large volume. We then would see the volume of water that the well produced after several minutes. Then with simple math, we can calculate the production capacity. But it is also important to understand that the well production can also vary over time. So the well may produce more or less water in the future than it does today.

How do you know how deep to drill?

We are not only looking for water. We are mainly looking for the rock that produces water. The depth of each layer of rock depends greatly on the location and elevation of the drill site. The formations are relatively flat below the surface. However, they may not be level. We use a gps to tell us the elevation of your drill site and we survey the area wells that we have drilled and compare their elevations. From this, we can estimate the depth that your well will need to be. However, we have found out on many occasions, that when God laid the foundations of the earth, He followed no rules. It is not uncommon to see formations rise or fall several hundred feet in a mile. For instance, we drill in one subdivision where the depth to the lower trinity is 760′ on one side of the road, and 840′ on the other. We can never be sure about the depth of your well until we actually drill.