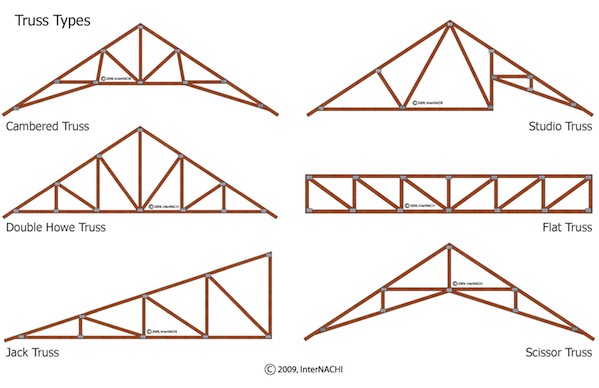

Comparing Roof Truss Types

Let's talk a little about roof trusses and some of the other choices. You need to know that all roof needs to be engineered and planned out by a professional for the dimensions of the lumber or design of the truss.

What Are Some of My Choices?

Traditional Stick Framing

Carpenters take 2x6, 2x8, 2x10 and 2x12 sticks of lumber to the jobsite. They hand cut and fit this lumber together into a roof.

Timber Frame

Craftsmen assemble timbers,

joinery and braces together to form a self-supporting skeleton structure.

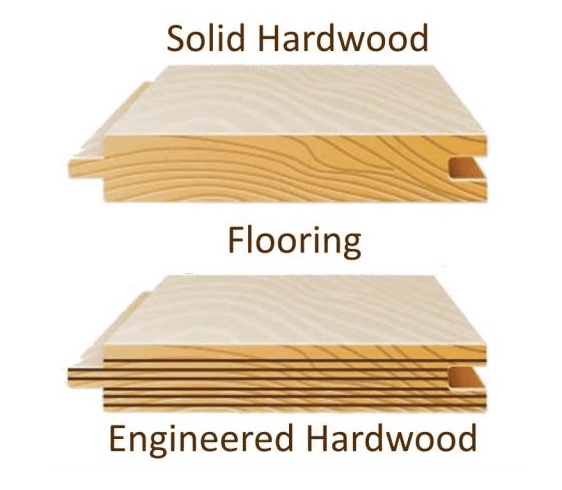

Engineered Wood Products

I-Joists, Glulam,

and LVL (laminated veneer lumber) wood products

are shipped to the jobsite, cut to fit, and made into ridge beams

and sloping joists for the roof system.

Truss Systems - 2 Primary Forms

Metal Plate Connected Wood Trusses

Engineered trusses are designed and

delivered to the jobsite with a truss placement

plan. Trusses are quickly erected and braced

onsite.

Steel Trusses

Light gauge steel trusses are

designed and delivered to the jobsite with a

truss placement plan. Trusses are lightweight,

able to be quickly erected and braced onsite.

Each method has advantages and disadvantages. Let's look at a few pro's and con's to assist

you in identifying which method is best for your situation.

Stick Framing |

|

|

Pro's - Not true in every case, but typically this method is the lowest cost for materials, if you have the time and the skilled labor required. If trusses cannot be delivered to the jobsite, conventional framing may be your only alternative. Vaulted ceilings. |

Con's - Slow to install and requires skilled labor. Requires scarce large lumber sizes. Smaller span capability. High jobsite waste. |

Timber Frame |

|

|

Pro's - Creates handsome exposed

timber-frame structures. |

Con's - Slow to install and requires skilled labor. Difficult to run ductwork, wiring, and pipes through. Slow to frame in. More expensive to insulate. |

Engineered Wood Products |

|

|

Pro's - I-Beams are suitable for steep sloping ceilings and much greater spans than typical stick framing. Trim-able ends great for angled or rounded walls. Engineered product with uniform quality. Glulam and Laminated Veneer

Lumber make strong beam

material. |

Con's - Difficult to run ductwork, wiring, and pipes through. Limited use in complicated roof lines, coffered ceilings, etc. May require special connections. |

Wood Trusses |

|

|

Pro's - Can be the lowest overall cost on large spans. Fast to install. Can span longer distances than dimensional lumber. |

Con's - Availability of getting them made in a timely manner. |

Steel Trusses |

|

|

Pro's - Lightweight and stiff, so installing is easy and fast. Straight ceilings for ceiling

attachment. No warping. |

Con's - More expensive than metal connector plate wood trusses. If not analyzed/designed by a

leading industry software

program, the joint connections

may be suspect. |

Benefits of Trusses for the Owner-Builder

Depending on design of the home and the greater the span of your roof from wall to wall, the truer the statements below become.

- Trusses may go up faster and easier, and may require less skilled labor.

- Trusses put you under roof faster, which helps in drawing construction loans.

- Ordering pre-assembled components generates less waste at the jobsite. This improves safety and reduces cleanup costs. On-site losses from improper cutting and damage are eliminated.

- Trusses can be built in a computer-aided manufacturing environment to assure accuracy and quality.

- Sealed truss designs are easily inspected.

- Expenses are accurately controlled because the roof truss

costs can be predetermined.

- Open web design allows easier installation of plumbing, electrical wiring and heating/cooling ductwork.

- Trusses provide clear spans so interior walls can be moved easily during remodeling or when making additions. It is very economical to remodel homes with trusses, versus frame houses.

More Roof Truss Information Available

An excellent resource to learn more about the roof truss is A Builder's Guide to Trusses, written by ITW Building Group in South Pompano Beach, FL. If you need to find a fabricator, try Alpine.